Fountain Elements

Classifications of fountain elements

1. Fountain control system

2. Water proof cable

3. Stainless steel water pump

4. Stainless steel pipe

5. Ball valve as spare parts of fountain

6. Solenoid valve

7. Underwater LED light

8. Water screen\projector\laser machine

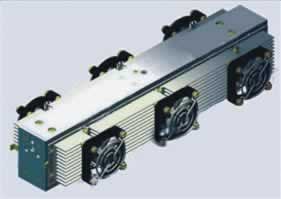

Audio system in fountain elements

Sprinkler system in fountain elements

Setting of fountain elements

1. You have to connect the fountain cables under unhydrous conditions. Besides that, you have to protect the cables with waterproof tape, insulation tape and high voltage insulation tape.

2. The exchange of underwater light have to be did under unhydrous conditions, too. You should tight the screw bolts.

Examination of fountain elements

1. Check of underwater light: you should check the light and tighten the screw per month to avoid the short circuit caused by water entering into the light.

2. Check of cable: the cables that are not in water should be checked per half year to avoid accidents.

3. Check of nozzles: To ensure water- fountain appearance and consistency, we should always reset the angle of the nozzle and prohibit the use of sharp objects when struck to prevent damage to the nozzle.

4. Testing of fountain electrical: you should maintain the electrical appliances on time. The testing and maintenance of fountain replacements should be gone on without electricity. For necessary live work, Security measures should be prepared and special monitoring site should be set.

The exchange of fountain elements

1. Spare parts of fountain should be run (high frequency of use every day for a change, the use of low-frequency time for a change) to prevent the device performance loss.

2. You should clean up all the dry statics in the pipeline while changing the solenoid valve diaphragm. You should tight the screws according to the diagonal sequence.

3. You should upgrade the computer and program per year.

Cleaning of fountain elements

1. Cleaning of fountain pump: you should clean the suction mouth of the fountain per month to avoid the congestion by pollutants. It will reduce working efficiency or even breaking the equipment. During the winter, the submersible pump as fountain placement in the cooling water must be deactivated winter shine, to avoid freezing damage the pump, oil cooler pump needs to close the valve.

2. Pipeline cleaning of fountain: you should clean it per year. Clean out all of the water in winter if you prepare to stop using it in case pipe cracking.

3. Cleaning of fountain nozzles and underwater light: clean them per half year. Be careful of Sprinkler riser and colorful lights.